Surface preparation

The surfaces to be coated must be clean, solid, dry and free of oil, grease and other impurities. Damp floors must be dried beforehand.

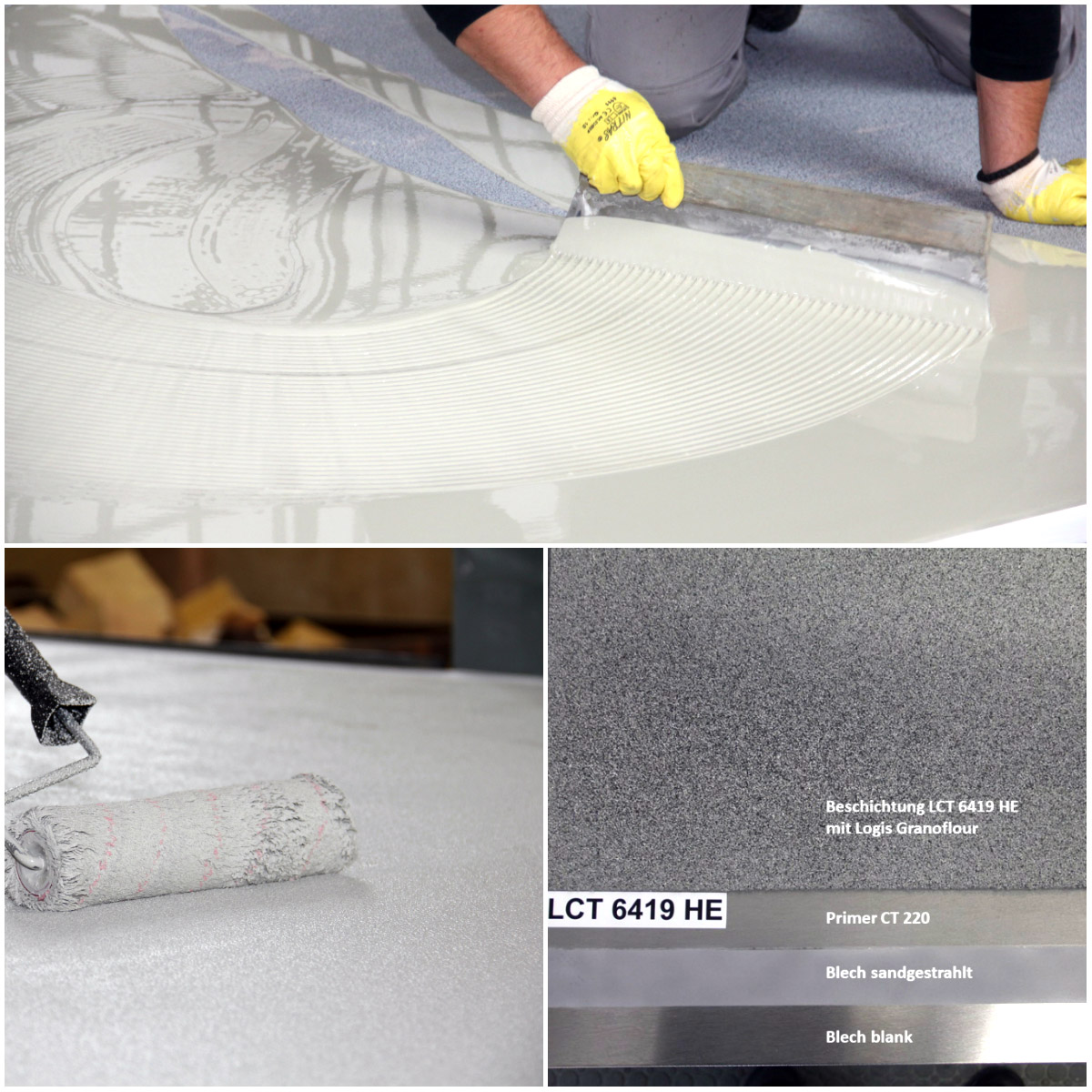

Grind surfaces (grain 40/60) and remove dust, corroded metallic substrates must be sandblasted, if possible. The panel joints must be sealed with 1C PUR sealing compound. Do not use silicone sealing compounds! If other substrates are to be coated, please consult us.

Mixing the components

The individual materials (adhesion promoter, coating, sealant) are supplied in the correct ratio of component A and component B. When mixing the components, please note the following:

First stir component A mechanically. Pour component B into the container of component A. Make sure that component B runs out completely. Partial quantities can be portioned in the correct mixing ratio using a balance (observe data sheet).

To achieve a homogeneous consistency and intensive mixing, the two components must be thoroughly mixed with a slow-running stirrer at approx. 300 rpm. The bottom and edge areas of the mixing vessel must also be covered. The mixing process must be carried out until a homogeneous, streak-free condition is achieved, but for at least 2 minutes. Do not use material from the delivery container. After thorough mixing, decant into a second, clean container and mix again for 1 minute. The temperature of the two components should be between 15 and 25 °C during mixing (see also Technical Data Sheets).