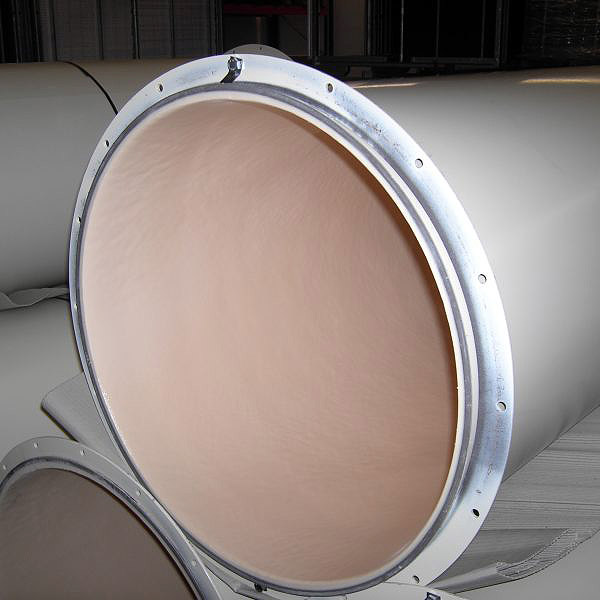

Our coating processes are suitable for a wide range of applications. When developing the processes and the coating materials, the focus is on the individual requirements of our customers and the result that is to be achieved with the coating. The necessary coating equipment and coating systems are developed in-house by LOGIS and its partner companies.

Coating plants and technology

The different properties that coatings must have and each application requires an individual solution: a perfect result can only be achieved if the coating material, the coating system and the coating technology are optimally matched.

The coating systems and techniques that LOGIS has designed and implemented for its customers include high and low pressure coating systems, spray guns with static mixers or counter-current injection – spray guns.

We advise our customers on the selection of the optimum technology. We ensure that the systems are delivered to our customers and installed. Employees are instructed and trained by us.